Trail Production (LVP)

Understanding Trail Production (LVP)

Trail production, or low-volume production (LVP), refers to the manufacturing of small to medium quantities of parts or products before full-scale production begins. It serves as a critical stage in the product development process, allowing companies to validate designs, test functionality, and gauge market demand without committing to large-scale production runs. It is particularly well-suited for startups, small businesses, and companies introducing new products or variations to existing ones.

The Benefits

Trail production offers a myriad of benefits for businesses looking to optimize their manufacturing processes:

- Cost-Effectiveness: By producing smaller quantities of parts or products, trail production minimizes upfront costs associated with tooling, setup, and inventory management. This allows companies to allocate resources more efficiently and mitigate financial risks.

- Flexibility: It offers unparalleled flexibility, allowing companies to adjust production volumes in response to changes in market demand, design iterations, or product variations. This agility enables quicker responses to customer needs and market trends.

- Quality Assurance: Despite producing smaller quantities, it does not compromise on quality. With advanced manufacturing technologies and rigorous quality control processes, companies can ensure that each part or product meets the highest standards of quality and reliability.

HuaYu Prototype’s Services

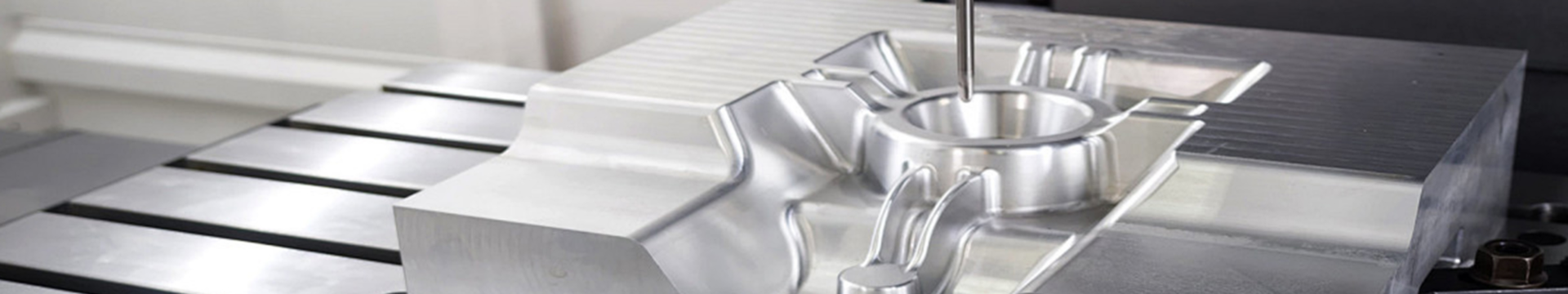

At HuaYu Prototype, we specialize in trail production services that leverage advanced manufacturing technologies, including CNC machining, 3D printing, and sheet metal fabrication, to deliver high-quality parts and products in small to medium quantities. Our trail production services offer the following advantages:

- Comprehensive Solutions: From prototype construction to final production, we provide end-to-end trail production services tailored to meet your specific needs and requirements.

- Advanced Technologies: Our state-of-the-art facilities are equipped with the latest manufacturing technologies, allowing us to produce parts and products with precision and efficiency.

- Flexibility and Scalability: Whether you need a few prototypes for testing or a small batch of production parts, we can accommodate your requirements with flexibility and scalability.

Contact us today.